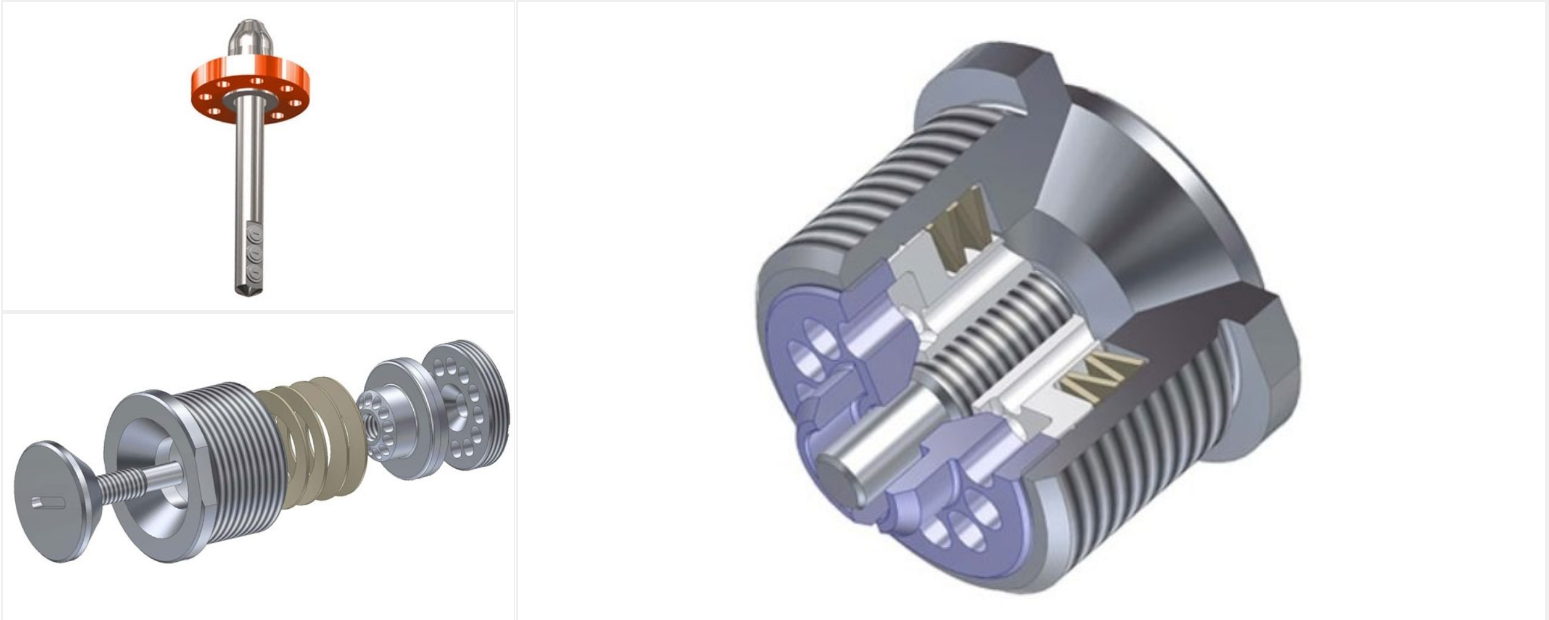

VO-II Variable Orifice Desuperheater

DESCRIPTION

Copes-Vulcan’s VO Variable Orifice Desuperheater is recognized industry wide as a versatile desuperheater. It is easily capable of meeting the most demanding needs for desuperheating in both the power and process industries.

The VO offers extremely fine control and exceptional turndown that is limited only by the rangeability of the coolant control valve itself.

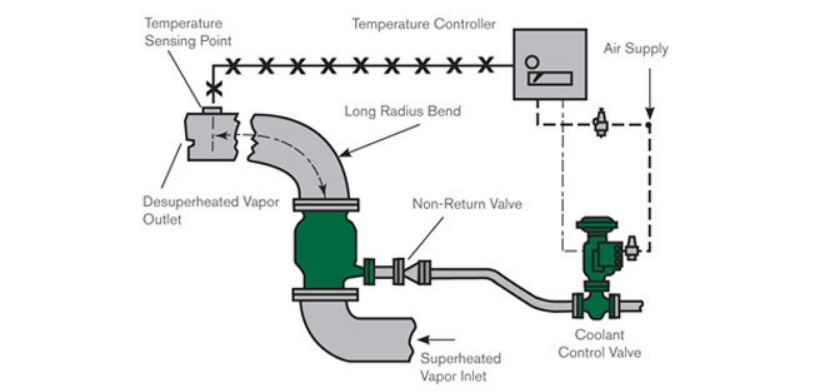

With excellent mixing of vapor and coolant, control is possible throughout the entire operating range to within 3± 5° F (± 2.5° C) of the set point which can be as close as 10° F (5° C) above saturation. The coolant pressure which is required at the inlet to the VO need only be 5 psi (35 kPa) above the pressure of the vapor being desuperheated.

Because virtually all of the desuperheating occurs within the VO body itself, the temperature sensing element can be as close as 14—20’ (4—6m) from the desuperheater outlet.

Features:

– The VO II offers extremely fine control and exceptional turndown that is limited only by the rangeability of the coolant control valve itself. Typically the unit can achieve a rangeability of 100:1 when matched with a Copes-Vulcan control valve fitted with Cascade trim design.

– Due to excellent mixing of vapor and coolant, control is possible throughout the entire operating range to within 5 °F (2.5 °C) of the set point, which can be as close as 10 °F (5 °C) above saturation.

– The coolant pressure, which is required at the inlet to the VO II need only be 5 PSI (0.35 bar) above the pressure of the vapor being desuperheated.

– Since virtually all the desuperheating occurs within the body itself, usually no pipe liners or long downstream straight pipe runs are necessary.

PRINCIPLE OF OPERATION

For more information about this product, please visit: https://www.celerosft.com/en-us/brands/copes-vulcan/products/mp-desuperheater-variable-orifice-voii