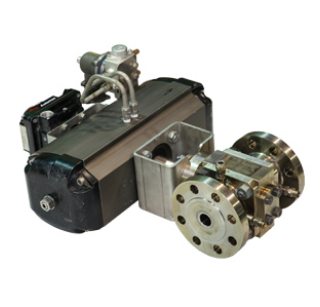

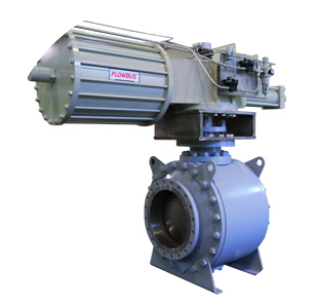

The KD VALVE are manufactured by new concept , Metal Seated Ball valve. so it has great properties for high-temperature, high-pressure, anti-pressure, anti-weardown, anti-corrosion on any industrial area.

Their products incorporate many unique design features for low fugitive emissions, simple in-line maintenance, and long service life, a Speacial manufacturer of Ball valve for problem solutions which happen to meet severe-service applications to the petrochemicaplant and chemical industry.

Feature

– High Hardness

– High Temperature (~550℃ Norminal Temperature)

– High Pressure (#150~#2500)

– Abrasion-Resistant (Poly-silicon, Sand, Catalyst, Ash line)

– Corrosion-Resistant ( H2S,HCl,Hydrocarbon, Steam)

– Low Friction Factor

– Gas Obstacle

Design

• ANSI B16.34, BS5351, ASMEⅢ

• SIZE RANGE : Standard Range : 1/2″ -16″ CLASS 150LB – 2500LB

• FACE TO FACE : ANSI B16.10 or to Customers special requirements.

• END CONNECTIONS : Flanged, Socket Weld, Butt Weld, Screwed, Hub, or to suit Customers requirements.

• Bubble tight bi-directional metal in metal sealing

• Anti-Blowout Stem

• Anti-Static Design

• Spring loaded seats leading to bubble tight sealing at low pressure, freedom from jamming at high temperatures and cavity relief via downstream seat.

• Trunnion mounted and floating ball design

• Full and reduced regular , v-port versions.

• Segment , Eccestric ball design.

For more information about their product, please visit: