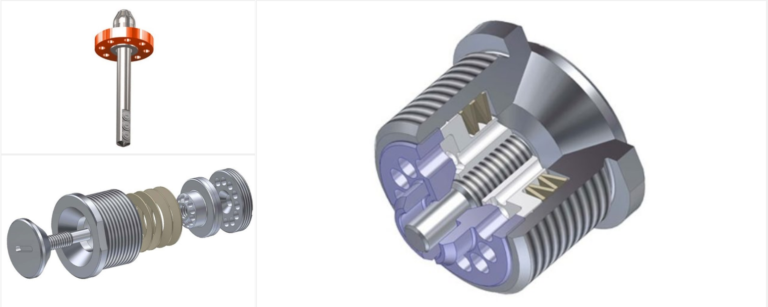

MA-I / MA-IU Mechanical Atomizing Desuperheaters

DESCRIPTIONThe Copes-Vulcan MA-I/MA-IU Mechanical Desuperheater is generally used for attemporating applications featuring steady loads. It is particularly designed for rugged service and can maintain final temperature to within 20°F (11°C) of saturation. Maximum cooling liquid capacity is 25,860 lbs/hr (11,700 kg/hr) at a nozzle differential pressure of 160 psi (1100 kPa) when using 100°F (38°C)…